- AustraliaEnglish

- BelgiumDutchFrench

- BrasilPortuguese

- CanadaEnglish

- FranceFrench

- GermanyGerman

- GlobalEnglishFrenchSpanish

- IndiaEnglish

- ItalyItalian

- JapanJapanese

- LuxembourgFrench

- Middle East & AfricaEnglish

- NetherlandsDutch

- PolandPolish

- PortugalPortuguese

- SpainSpanish

- SwedenSwedish

- TurkeyEnglish

- United KingdomEnglish

- United States of AmericaEnglish

SMA's expertise on topics of solar energy and photovoltaics for all applications

Energy topics

Safety and repowering of PV systems. Design and efficiency of PV power plants. Information on new business models. Here you will find exciting white papers, sound expertise, and interesting background information on solar energy and the energy supply of the future. For private PV system operators and solar power professionals. For companies and installers. For EPC companies, investors, and PV power plant operators.

Solar system during power outage

What happens to your PV system during a power outage?

Stand-Alone Solar Solutions

Produce and consume 100% of your own energy

EEBus for the Smart Home

Intelligently network household appliances

Cybersecurity: how SMA keeps your energy systems and grids protected

Cybersecurity is now a critical foundation for every renewable energy project—discover why it matters more than ever.

Why reactive power matters

Ensure grid stability and maintain voltage with innovative technology.

SiC MOSFET technology - shaping the future of clean energy

The switch from IGBTs: How SiC MOSFETs represent the next level of performance for large-scale power conversion systems.

High Quality, High Availability

Discover how SMA’s high-availability PV solutions drive long-term performance and build investor trust.

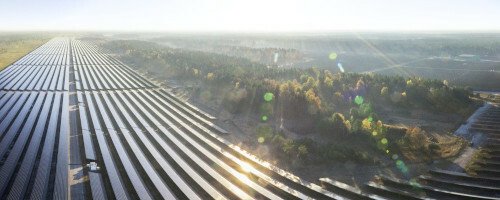

Oversizing is the Key to Higher Profitability

SMA technology offers maximum freedom and safety

1500 volt and SMA Design Reserve

True 1500 V technology for the new generation of PV power plants

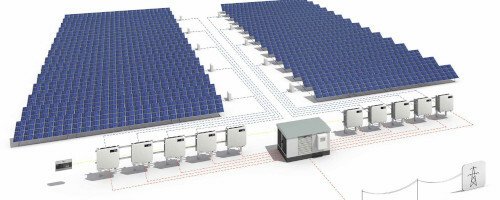

Centralized System Layout – Decentralized Inverter Concept

Which layout is best for a large PV power plant?